Don’t Journey Alone

Heroes Always Have Navigators…Advisors They Can Trust

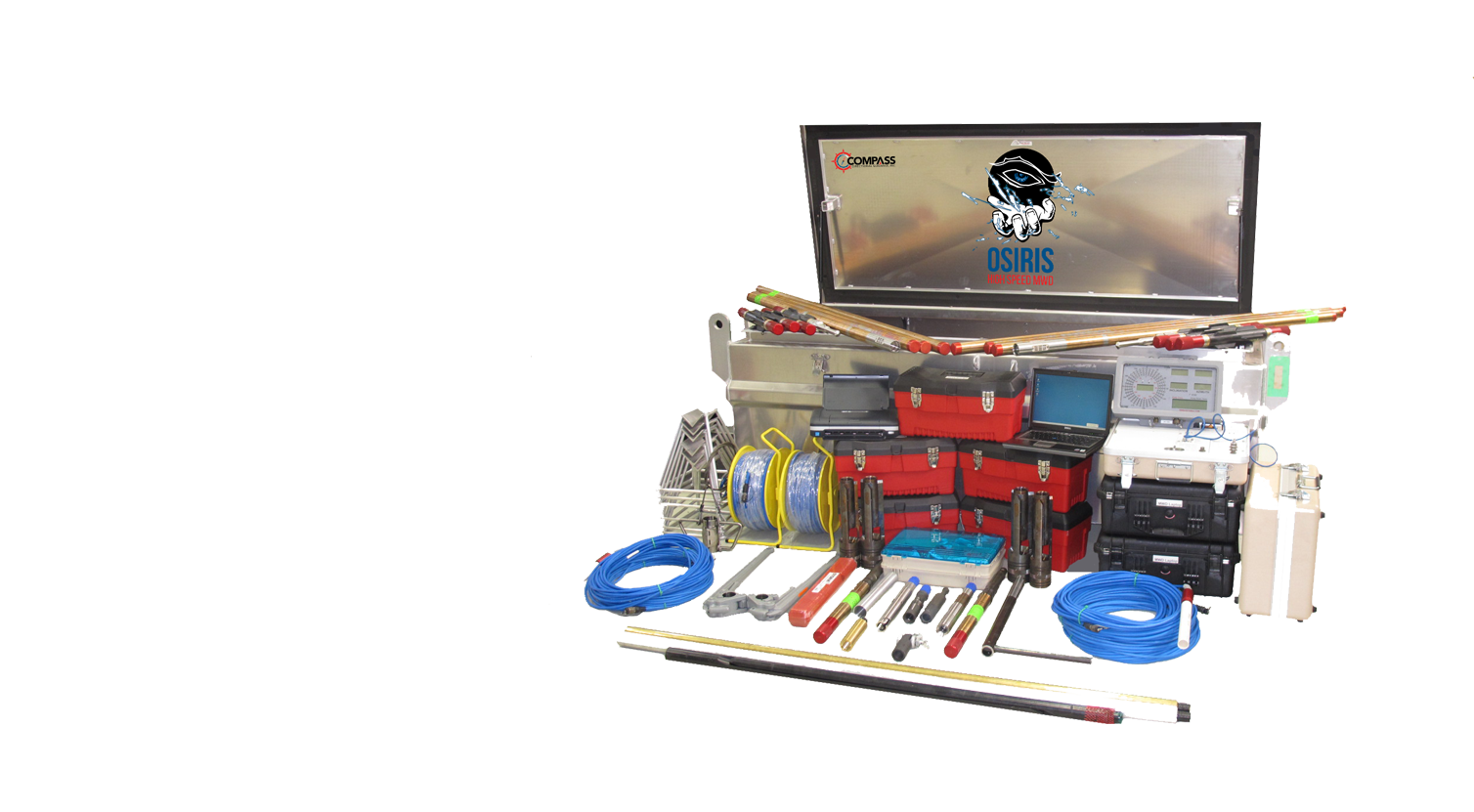

MWD PRODUCTS

Get everything you need to overcome challenges.

Legendary reliability ready to be deployed on a callout basis anywhere in the world with rock solid fleet maintenance available in two Texas locations; Midland and Houston.